- info@hightoptools.com

- Monday - Sunday 9.00 - 18.00

WhatsApp: +86 18162052962

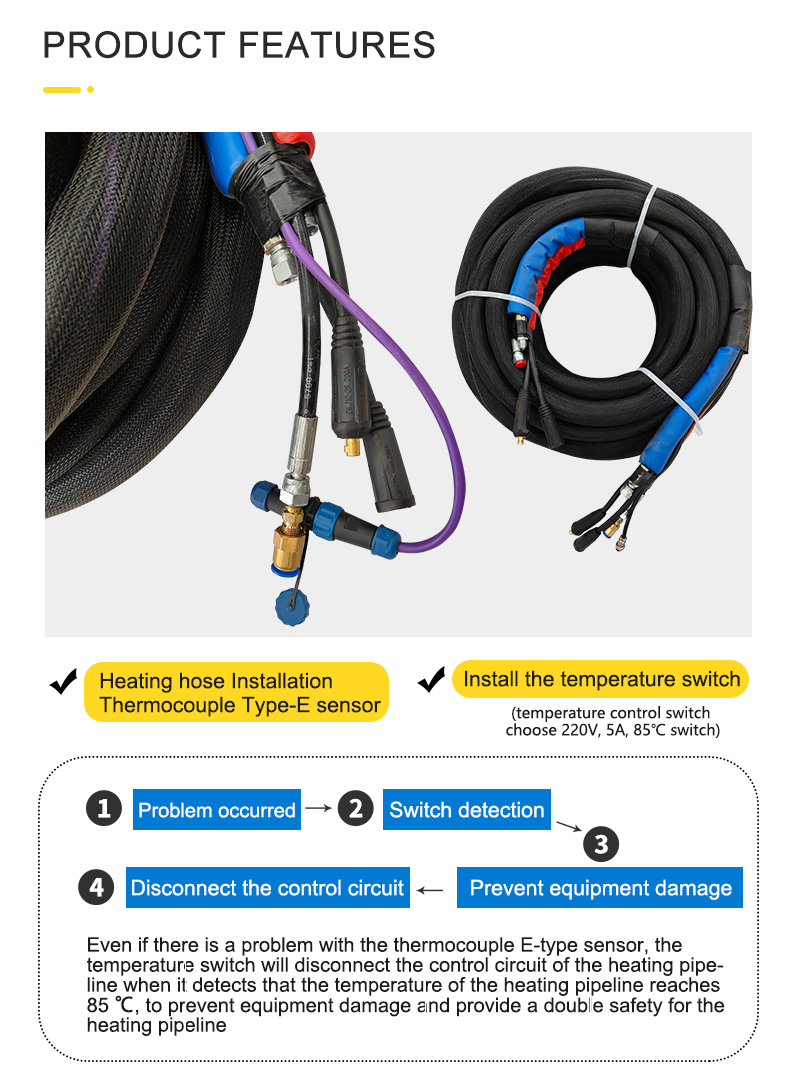

Heating hose

Heating hose Installation

Thermocouple Type-E sensor

Install the temperature switch(temperature control switch

choose 220V,5A,85°℃ switch)

Even if there is a problem with the thermocouple E-type sensor, the

temperature switch will disconnect the control circuit of the heating pipe-line when it detects that the temperature of the heating pipeline reaches 85 'C, to prevent equipment damage aind provide a double safety for the

heating pipeline

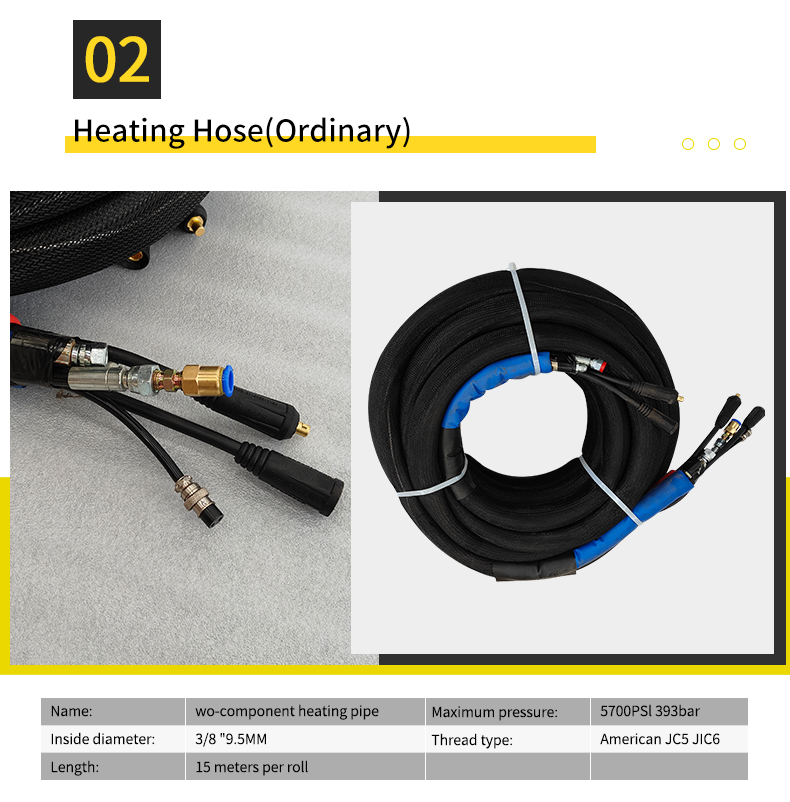

Heating Hose(Ordinary)

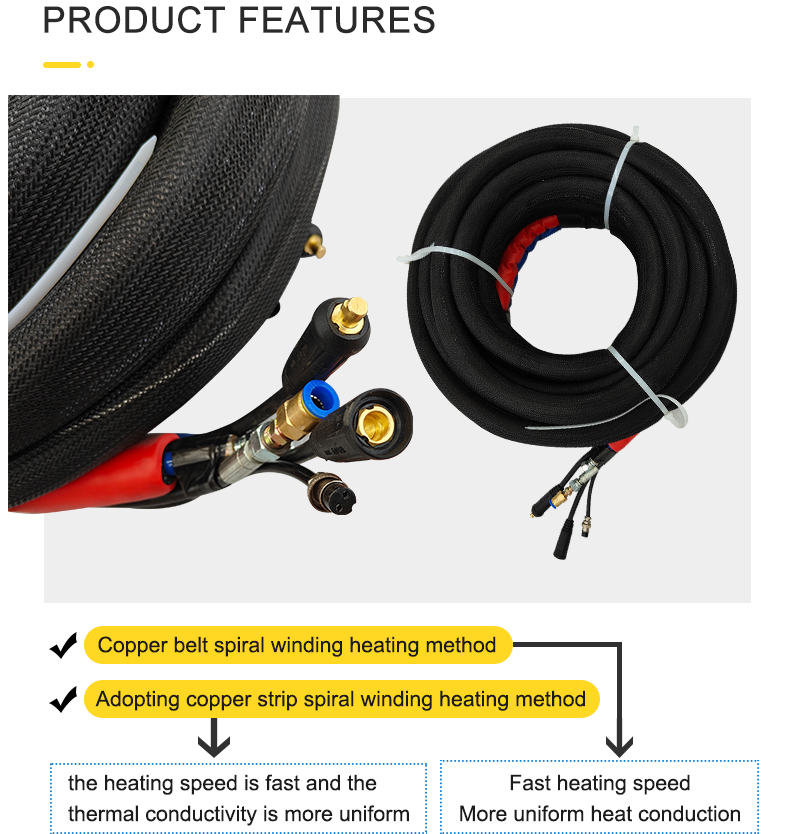

Copper belt spiral winding heating method

Adopting copper strip spiral winding heating method

the heating speed is fast and the

thermal conductivity is more uniform

Fast heating speed

More uniform heat conduction

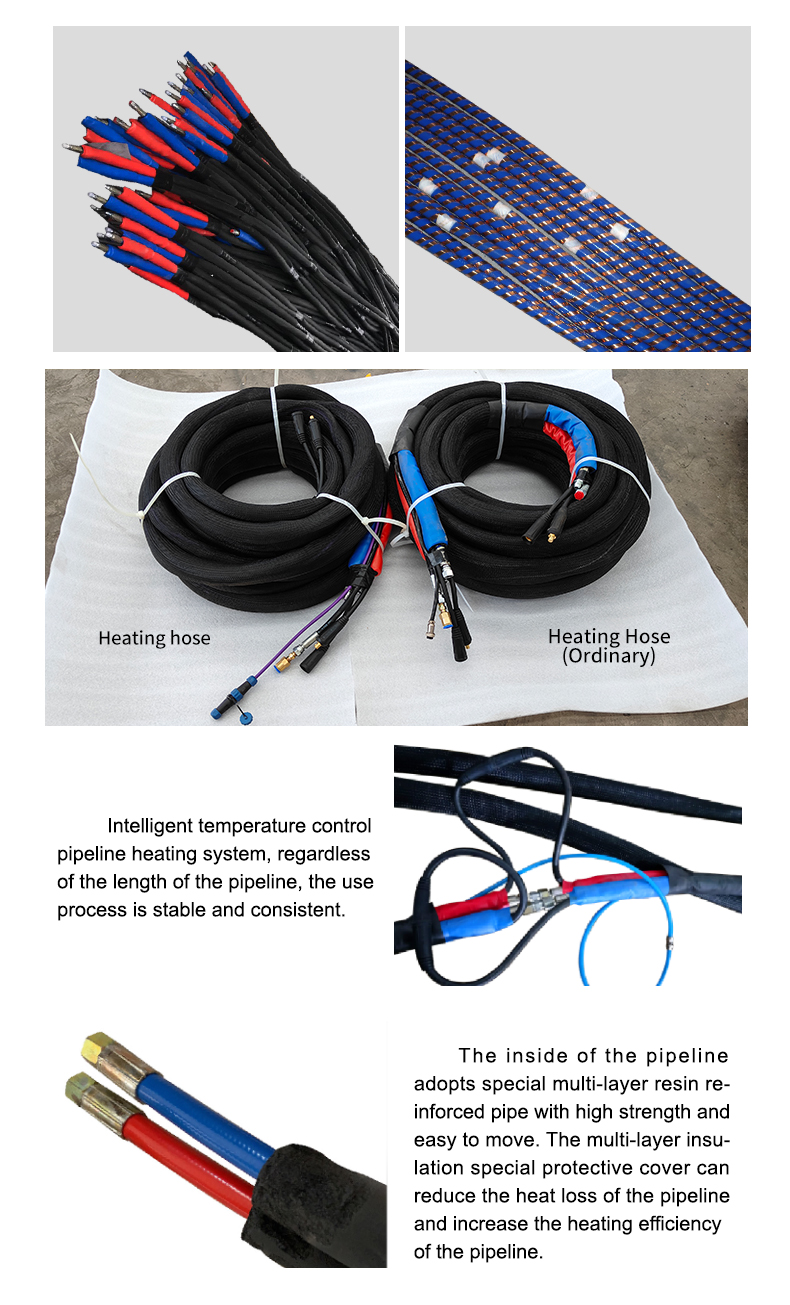

intelligent temperature contro!

pipeline heating system, regardless

of the length of the pipeline, the use

process is stable and consistent.

The inside of the pipeline

adopts special multi-layer resin re.

inforced pipe with high strength and easy to move. The multi-layer insu.

lation special protective cover can

reduce the heat loss of the pipeline and increase the heating efficiency of the pipeline.

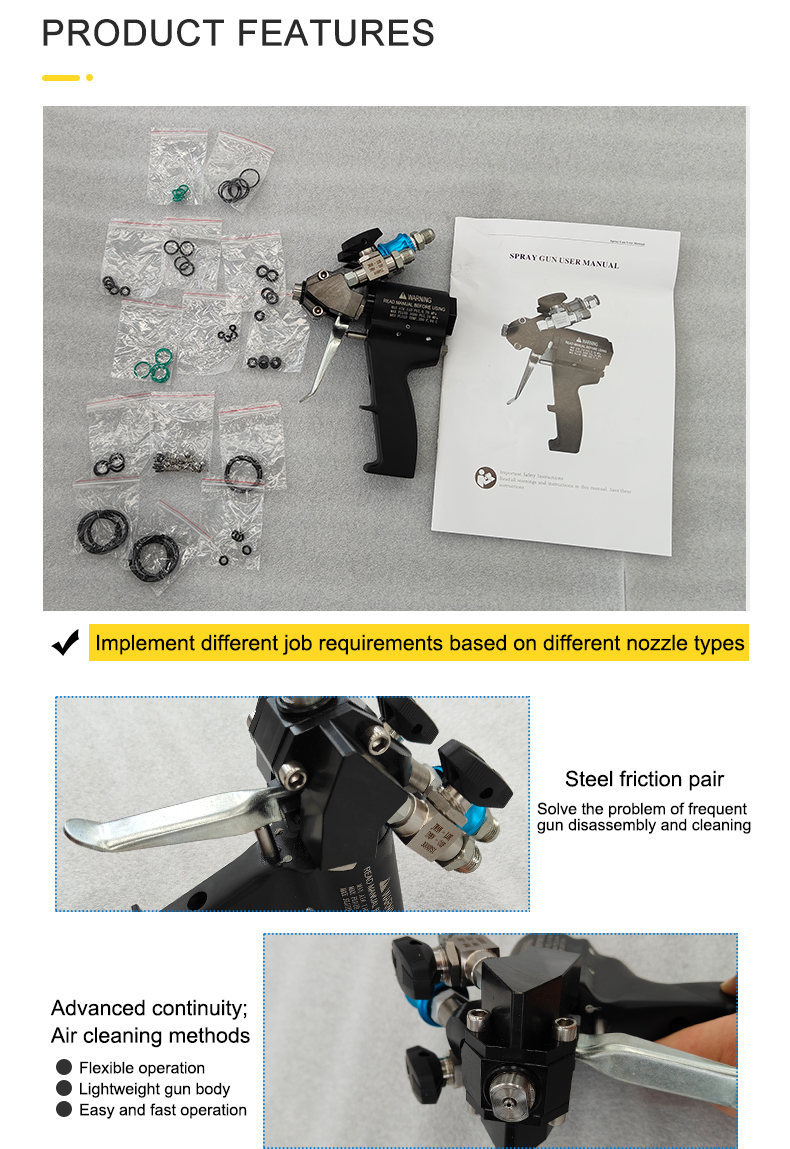

Spray gun Steel friction pair Solve the problem of frequent gun disassembly and cleaning

Advanced continuity;

Air cleaning methods

Flexible operation

Lightweight gun body

Easy and fast operation

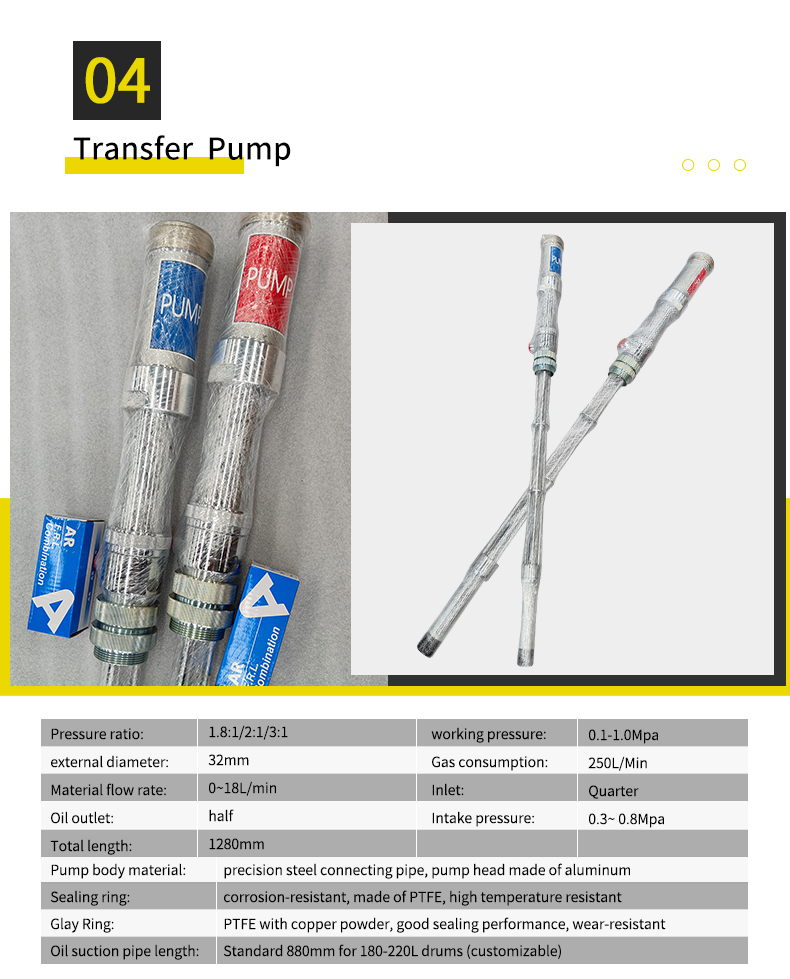

Transfer Pump

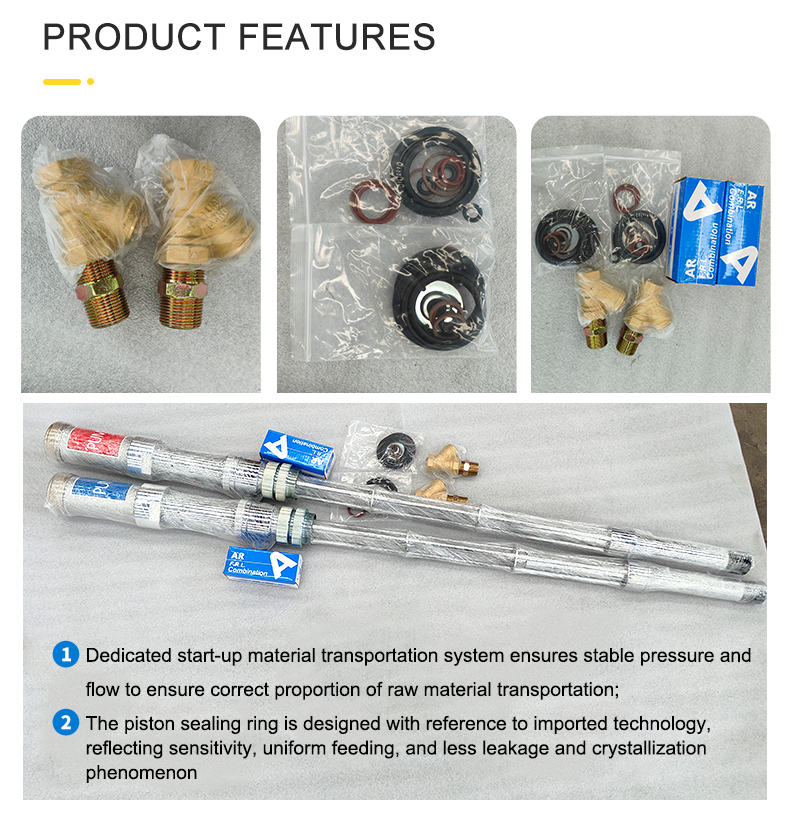

Dedicated start-up material transportation system ensures stable pressure andflow to ensure correct proportion of raw material transportation;

The piston sealing ring is designed with reference to imported technologyreflecting sensitivity, uniform feeding, and less leakage and crystallizationphenomenon.