- info@hightoptools.com

- Monday - Sunday 9.00 - 18.00

WhatsApp: +86 18162052962

CNMC-HP10 Polyurethane foam sprayer Instruction

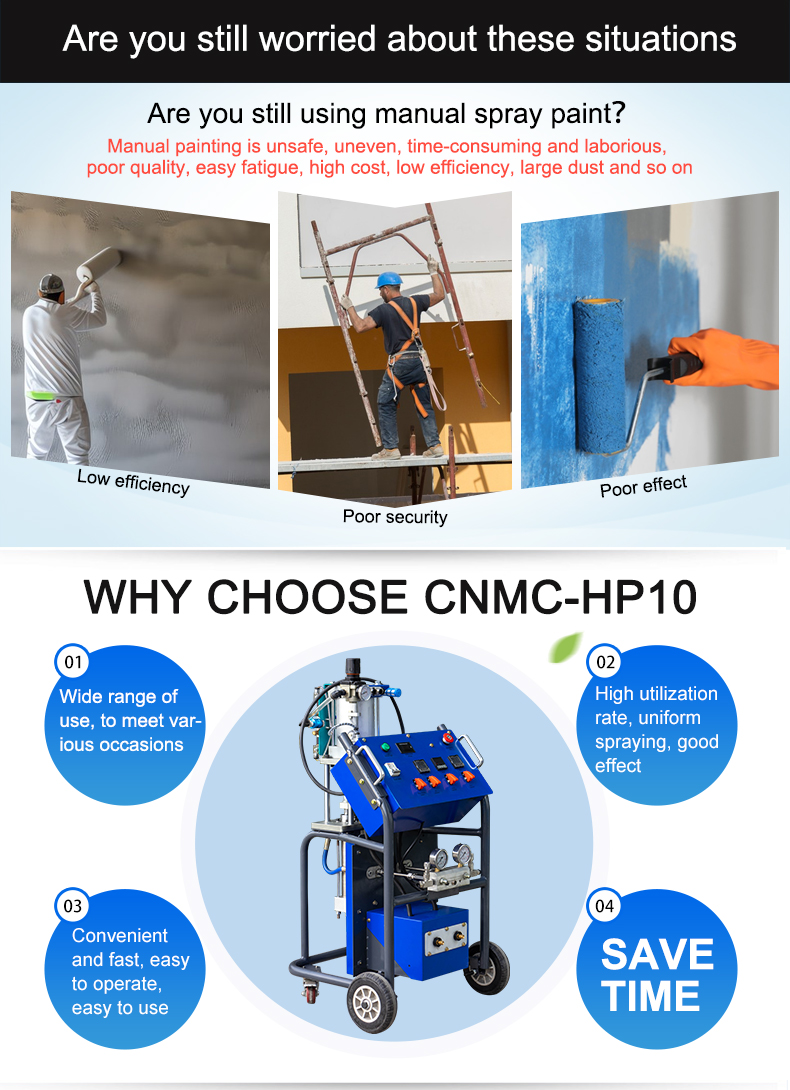

Manual painting is unsafe, uneven, time-consuming and laborious,poor quality, easy fatigue, high cost, low efficiency, large dust and so on.

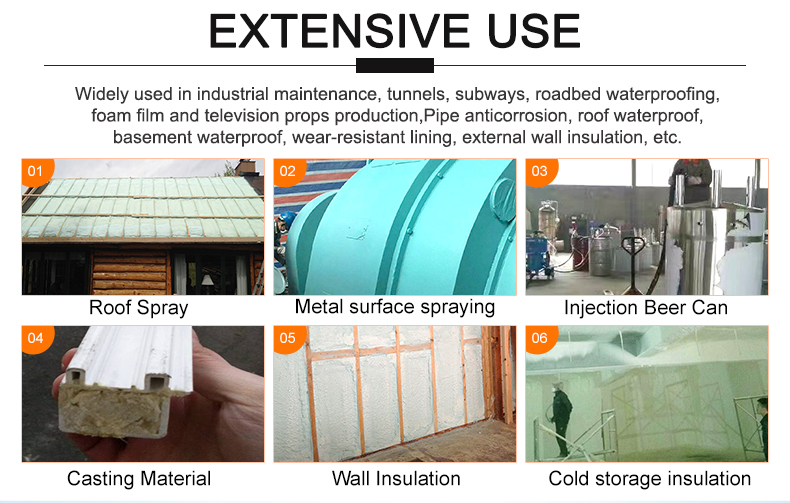

Widely used in industrial maintenance, tunnels, subways, roadbed waterproofingfoam film and television props production,Pipe anticorrosion, roof waterproof,basement waterproof, wear-resistant lining, external wall insulation, etc.

Real-time monitoring of voltage and current

Add Voltmeter and Ammeter , so The voltage and current conditions inside themachine can be detected every time

Humanized Operation Panel

One-button operation and digital display counting system,easy to master the

operation method

PIPELINE CONNECTION DIAGRAMOF THE WHOLE MACHINE

Optimize circuit layoutThe electric circuit design is more humanized.engineers can check the circuit problems more quickly

Large Power Cylinder

The big size cylinder makes the spraying more powerful andthe atomization effect better.

More advanced technology 04Adpot some technologies from Poly-craft USA brand,heated hose andspray guns can be used on Graco machines and HP10 spray machine

Spray Gun

Three functions together : polyurethane injectionpolyurethane insulation spray ,polyurea waterproof spray

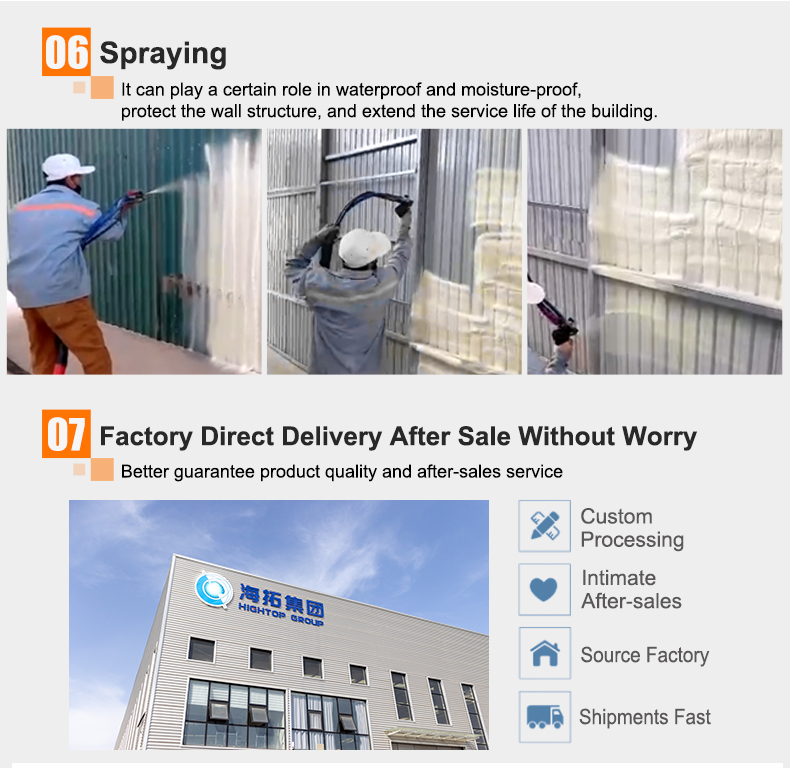

Spraying

It can play a certain role in waterproof and moisture-proof,protect the wall structure, and extend the service life of the building

Factory Direct Delivery After Sale Without WorryBetter guarantee product quality and after-sales service

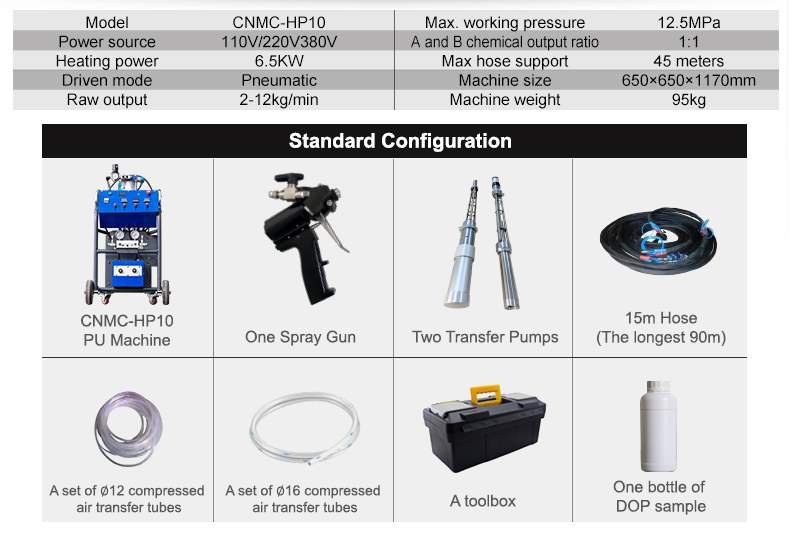

CNMC-HP10 Polyurethane foam sprayer Parameter

|

Model |

CNMC-HP10 |

Max.working pressure |

12.5MPa |

|

Power source |

110V1220V380V |

A and B chemical output ratio |

1:1 |

|

Heating power |

6.5KWV |

Max hose support |

45 meters |

|

Driven mode |

Pneumatic |

Machine size |

650x650x1170mm |

|

Raw output |

2-12kg/min |

Machine weight |

95kg |

CNMC-HP10 Polyurethane foam sprayer Images